Materials

Stainless steel is not just stainless steel.

The different areas of application and influences on the end products are decisive for us right from the start. Choosing the right material is an important factor for our customers.

We offer a wide range of materials and are happy to help our customers choose the right one for them.

Many years of experience and industry knowledge is our key to success.

Austenitic steels

Nickel Alloys

Special Alloys

Other materials are available on request

Request Materials nowSeamless tubes acc. DIN EN 10216-5

Seamless tubes acc. DIN EN 10216-5

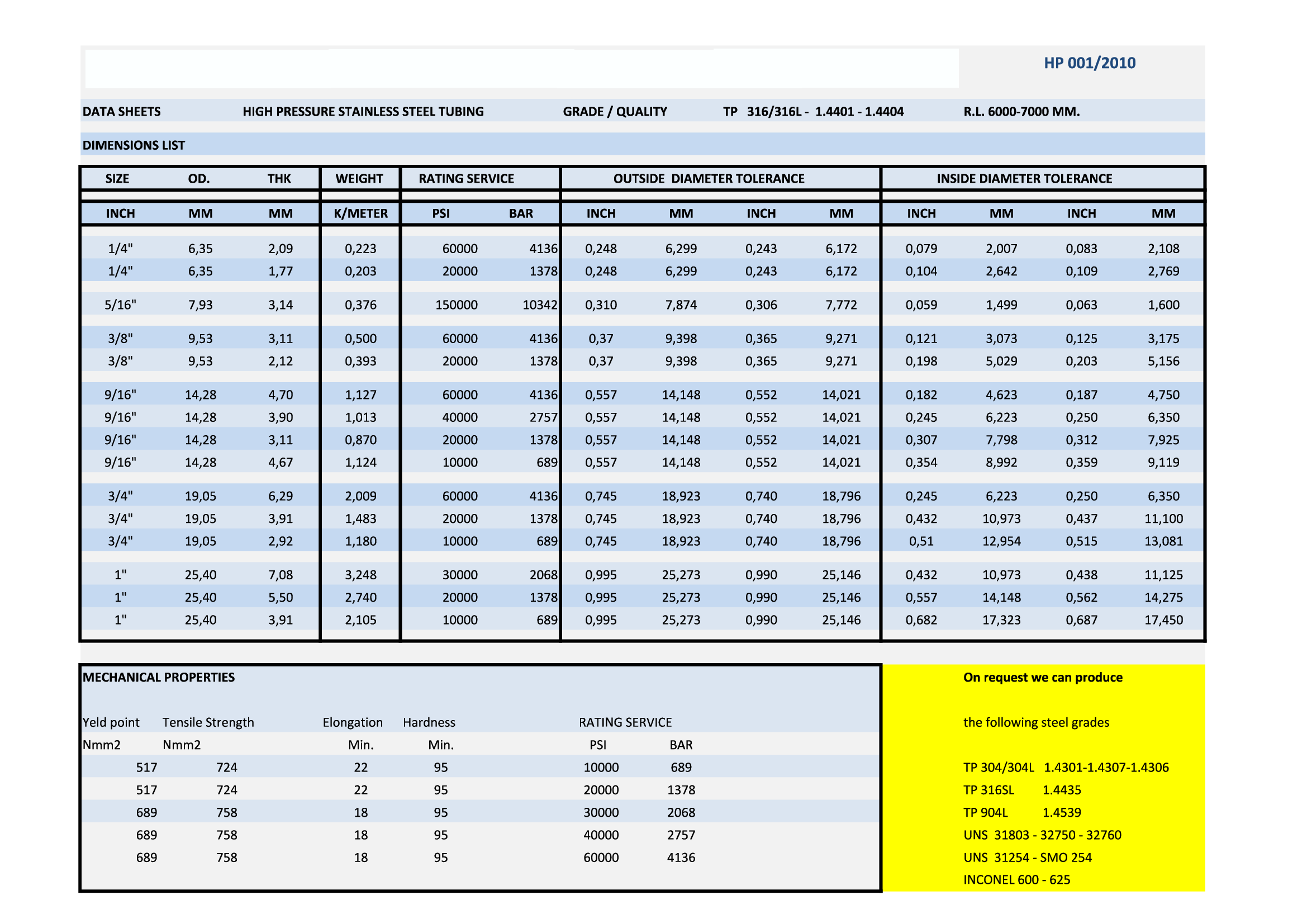

We offer to our customers cold-drawn seamless stainless steel tubes from new production. This manufacturing process enables us to offer our customers great advantages.

The mechanical properties of the final tube can be adjusted to customer needs. Tensile strength, elongation, surface finish and much more - we do what the customer needs.

| Outer diameter | from 0.5 to 60 mm (tolerance: from + / - 0.005 mm) |

| Wall thickness | from 0.05 to10 mm (Tolerance: from + / - 0.005 mm) |

| Execution | Annealed, half-hard and hard or according to the tensile strength specification |

| Finishing | Bright drawn , pickled, grinded or polished |

| fixed lengths | from 3 to 20.000 mm, Tolerances by arrangement (depending on OD) |

Welded-redrawn tubes acc. DIN EN 10217-7

Welded-redrawn tubes acc. DIN EN 10217-7

We offer our customers welded-redrawn stainless steel tubes from new production. This manufacturing process offers a number of advantages over a pure welded tube. A high-quality end product is produced from a welded tube by repeated reduction steps.

The mechanical properties of the final tube can be adjusted to customer needs. Tensile strength, elongation, surface quality and much more influence the later processability and quality of your products.

| Outer diameter | from 0.5 to 60 mm (tolerance: from + / - 0.005 mm) |

| Wall thickness | from 0.05 to10 mm (Tolerance: from + / - 0.005 mm) |

| Execution | Annealed, half-hard and hard or according to the tensile strength specification |

| Finishing | Bright drawn , pickled, grinded or polished |

| fixed lengths | from 3 to 20.000 mm, Tolerances by arrangement (depending on OD) |

Welded or welded-redrawn tubes in Coil acc. DIN EN 10217-7

Welded or welded-redrawn tubes in Coil acc. DIN EN 10217-7

Tubes in coils are of great advantage for certain areas of application. Reduced waste and easy storage are just a few of the benefits our customers have.

We produce tubes as coil in welded and welded-redraw versions.

| Outer diameter | from 0.5 to 12 mm (tolerance: from + / - 0.005 mm) |

| Wall thickness | from 0.05 to 1.50 mm (Tolerance: from + / - 0.005 mm) |

| Execution | Annealed, half-hard and hard or according to the tensile strength specification |

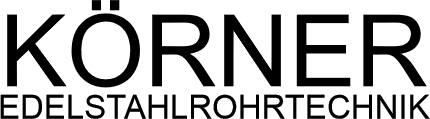

High-pressure tubes

With more than 35 years of experience in the manufacture and processing of seamless stainless steel tubes, we are your reliable partner if you are looking for tubes for increased pressure needs.

We have a large stock range of high-pressure tubes from 1/4" (6.35 mm) to 1" (25.40 mm). Pressure loads of up to 10,000 bar (150,000 psi) can be implemented with our tubes. We are also able to manufacture pipes according to your specification.

Fixed lengths

Fixed lengths

We are also happy to manufacture fixed lengths starting from 1.00 mm in length for our customers. We offer cutting, deburring, vibratory finishing, tumbling and much more. From sampling to series production.

| Outer diameter | from 0.5 to 50 mm |

| Wall thickness | from 0.05 bis 10.00 mm |

| Length | from 1.00 to 2000 mm |

| Finishing | Ends deburred by drill, brush, tumbling or electrolytically |

Welded tubes and pipes

Welded tubes and pipes

A stainless steel strip formed over rollers is turned into a high-quality tube using a laser or TIG welding process. Welded tubes manufactured according to DIN EN 10217-7 can be obtained from us in both annealed and unannealed versions.

From an inside diameter of 16.00 mm, the inner seam can also be smoothed on customer request. The outer weld can be removed for all dimensions or the entire surface can be grinded or polished.

| not annealed | EN10217-7 Ausf. WO |

| annealed | EN10217-7 Ausf. W2R |

| Outer diameter | from 3.0 mm to 127 mm, tolerance D3 oder D4 |

| Wall | from 0.2 mm to 3.00 mm, tolerance T3 oder T4 |

| Length | from 3 mm to 32.000 mm, tolerance on agreement (dependeing on the OD) |

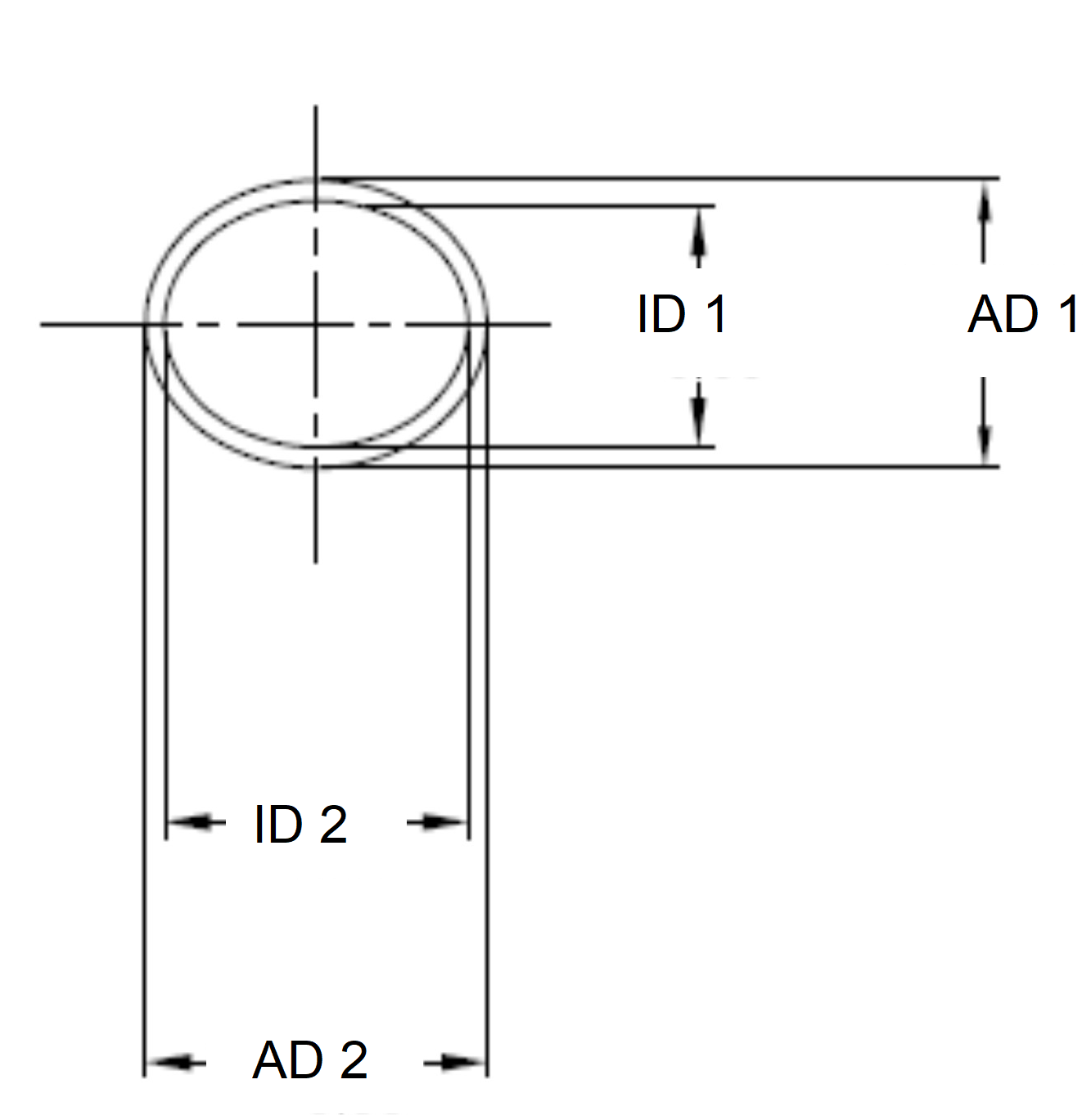

Profiled- and oval tubes

Profiled- and oval tubes

Welded - redrawn tubes with special shapes such as square tubes, oval tubes, profiled tubes, drilled tubes and much more.

We manufacture specially shaped tubes according to customer drawings with fixed radii, required straightness and torsion. Outside diameter 3.00 to 12.00 mm.

Bended tubes and assemblies

Bended tubes and assemblies

We offer our customers almost all further processing steps for welded and redrawn tubes with an outside diameter of up to 10.00 mm. With modern CNC bending systems and a laser cutting center, we can respond to the wishes of our customers.

From sample production to series production, we are your reliable partner.

Certification and quality

All from a single source

Thanks to our machinery and a network that has grown over decades, we are able to offer our customers many additional processing steps. Cutting, bending, grinding, polishing and much more are part of our service. We take over the coordination and planning for our customers and deliver finished parts according to their wishes.

More about our company